Composite Manufacturing & Facilities

VX Aerospace is AS9100:2016 and ISO 9001:2015 Certified Facility. With a broad range of composites manufacturing capabilities utilizing carbon fiber, glass, aramids, and reinforcements and multiple resin systems.

High temperature computer-controlled vacuum curing of composite laminates in a 40’x12’x9′ oven

High temperature 48”x 72”x 46” oven

4000 sq. ft. environmentally controlled clean room for production part and tool laminating

5’ x 12’ CNC router for machining tooling, masters, and fixturing

15,000 sq. ft. assembly and fabrication space

State of the art dust collection system

Our facility can accommodate large-scale fabrication and assembly from discrete components to full top-level assemblies.

We combine design and manufacturing expertise to reverse engineer existing parts or design new components while manufacturing them to stringent quality standards.

Our ability to understand the complete aircraft along with the integrated structural components helps us better design and fabricate composite parts and assemblies for the aviation community.

Assembly & Integration

VX has over a decade of fabrication and assembly experience producing RFI (Ready for Installation) parts and assemblies for commercial and DoD customers.

We take pride in our ability to provide our customers with original design support and timely and collaborative consultations to ensure an efficient and exact final assembly.

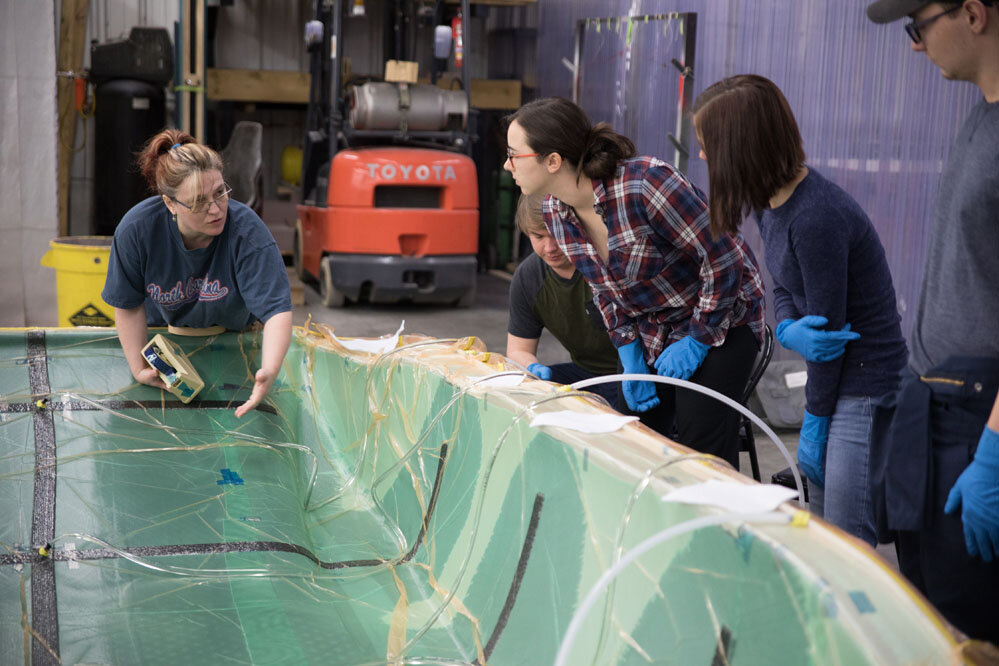

Dash X Tooling Demonstration at CAM-X, Orlando, FL

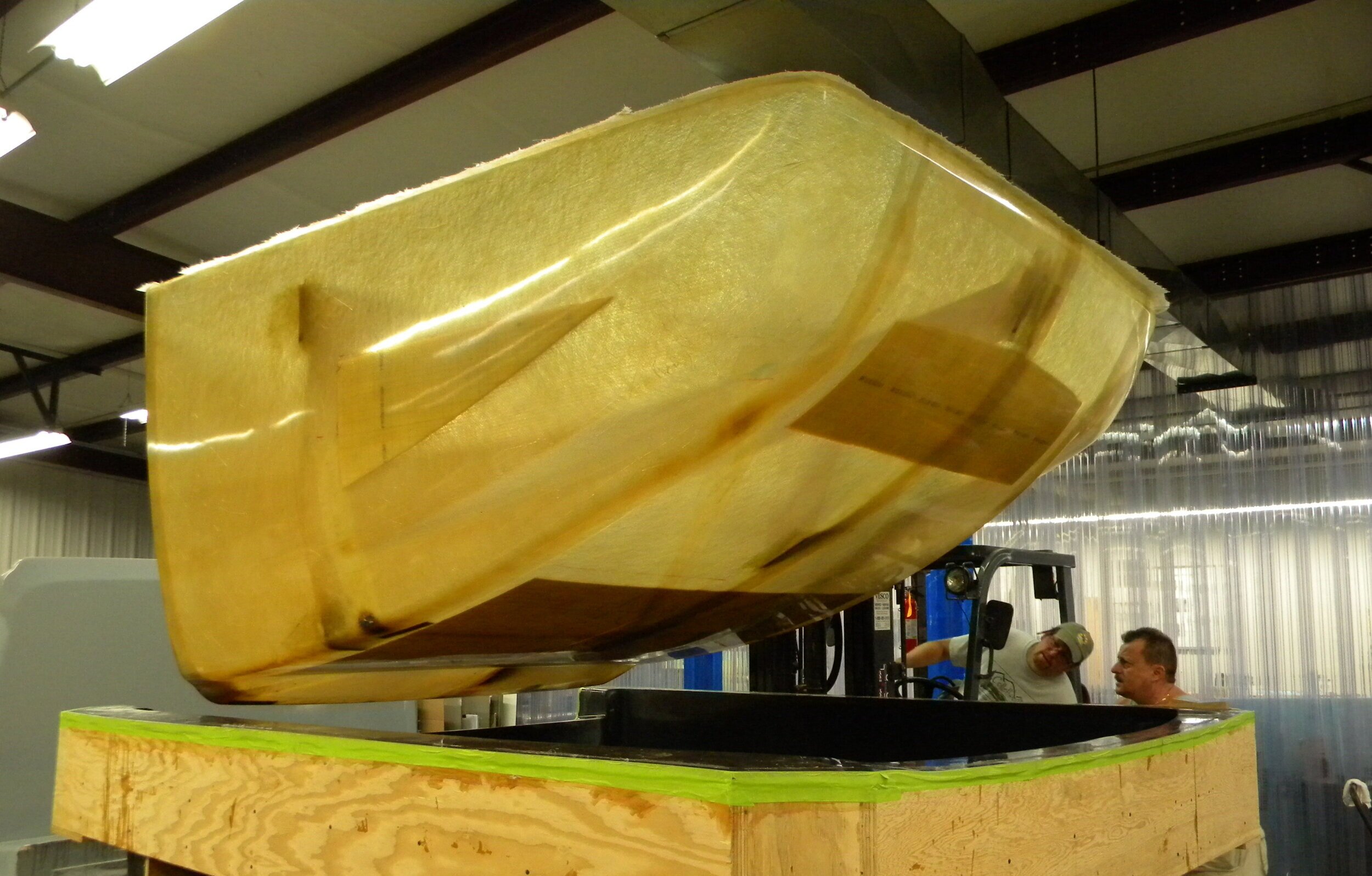

Tooling & Mold Design

VX Aerospace designs and manufactures composite tooling in-house. We have the expertise and equipment on-site to do so. We understand the aerospace industry requirements for composite tooling and consistently meet those requirements. With the ability to design and manufacture both quickly and with precision, we’re able to provide our customers with unparalleled turnaround times.

Volvo Semi-Truck Hood Tooling

Rapid Prototyping

VX provides its clients with rapid prototype development using low temperature direct machined molds. This saves time and money for short run and prototype parts.

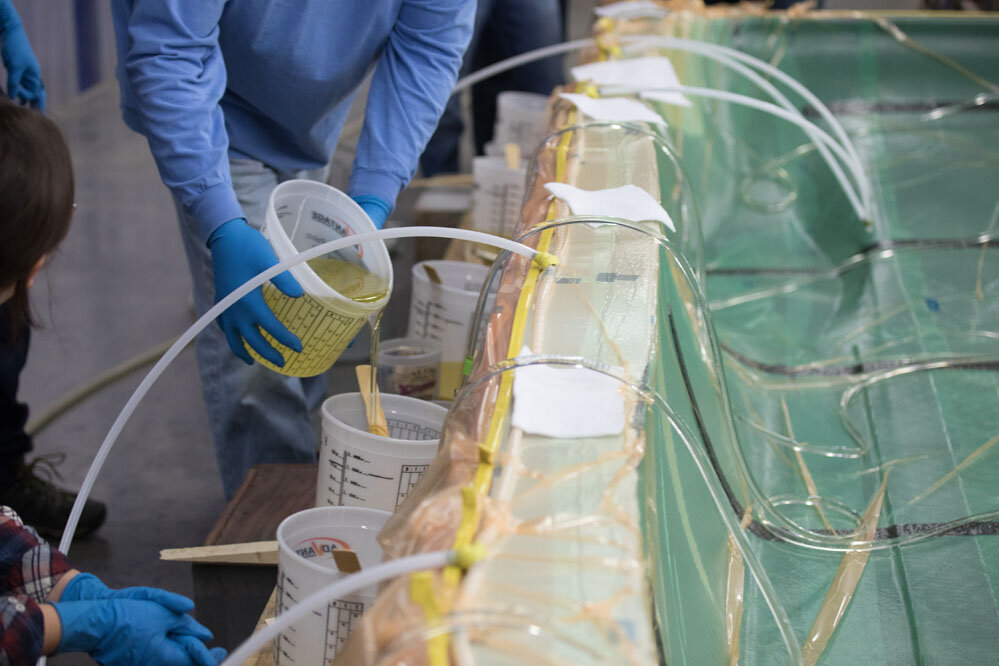

All prototype design is geared towards development into full rate production to minimize redesign time between initial prototype, first article, and production. We utilize our large on-site oven to produce out-of-autoclave oven cured composite parts including both resin transfer molding and vacuum-assisted resin transfer molding processes. This allows us to provide our clients with high strength parts with ideal dimensional tolerances and exceptional part quality.

Manufacturing Design

From inception to completion, VX Aerospace executes composite part design and engineers fully integrated aerospace systems. Whether our client is in need of a single part, assembly or airworthy vehicle, we can design, fabricate and assemble it. Our capable team of engineers and manufacturing specialists that efficiently apply their knowledge and skills to troubleshoot and reconfigure design elements to meet customers needs.

Whether our client’s application is in need of exact tolerances, particular physical properties or definite strength requirements, we’re easily able to implement experience to meet quality standards at efficient turnaround times.